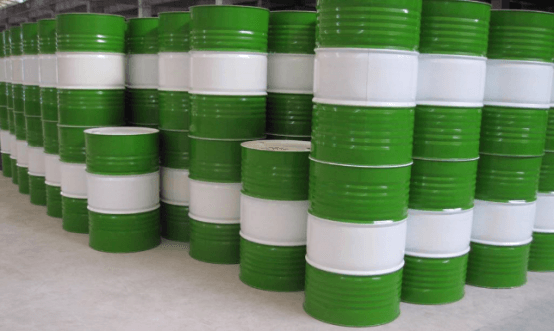

Chemical packaging has emerged as the times require since the birth of the industrial revolution. At present, the main packaging methods include traditional packaging containers such as steel drums, commonly known as iron drums, plastic drums and IBC drums, and a relatively new type of chemical liquid granules that have just been launched on the market. Powder collapsible sustainable recyclable packaging solution. The plastics industry occupies an important position in the field of chemical packaging.

Since the 1980s, a large number of 200-liter plastic drum production lines have been introduced in China, and the market has performed strongly. Some steel drum enterprises have closed down, and the market share of some steel drum enterprises has decreased sharply. Due to the rapid development of the domestic chemical industry, the demand has surged, 200 The market for liter steel drums and 200L plastic drums is growing at the same time.

After entering the 21st century, with the rapid development of China's petroleum and chemical industry and food processing industry, the IBC drum blow molding machine has been researched and developed to replace the 200L double ring barrel. And the first German companies Mauser and Schutz brought technology and equipment to China. Since the filling capacity of 1 ton barrel = the filling capacity of 5 200-liter plastic drums. Four 200-liter plastic drums occupy the same volume, but can only hold 800 liters of material. A 1000-liter IBC drum needs to be filled once, sealed once, and labeled once, while a 1,000-liter plastic barrel (5 200-liter barrels) requires 5 times of filling, 5 times of sealing, and 5 times of labeling. Therefore, IBC drum packaging saves costs and improves the work efficiency of customers. Compared with plastic drums and iron barrels, IBC barrels have the best cost control. So Schutz and Mauser quickly occupied the Chinese market.

With their technological blockade, they almost occupied the vast majority of the chemical packaging market share in China, forming a monopoly,and raising prices. Therefore, China's machinery manufacturing enterprises invest in research and development. Gradually break the monopoly with high-quality and inexpensive equipment. And successfully occupy the Chinese market, and gradually expand to overseas. The Juncon intelligent IBC drums blow molding machine is gradually gaining a firm foothold in the step-by-step research and development accumulation. With its excellent quality and stable machine performance, it has successfully entered the domestic and foreign markets.

Advantages of Juncon IBC drum blow molding machine: The IBC drum is composed of an inner container and a metal frame. The IBC container inner is blow-molded with high-density polyethylene, which has high strength and corrosion resistance. IBC drums which can greatly reduce the cost of production, storage, transportation and operation. Save manpower and material resources. Compared with traditional packaging, storage can save more than 30% of space, and forklifts are used for loading and unloading, reducing manual handling. Filling: one IBC container drum/barrel = 5 pcs 200L barrels/drums, reducing repeated operations during the filling process, and avoiding leakage, waste and pollution during the filling process. In short, IBC drums/barrels are more convenient to use, economical and durable, and IBC containers /barrels can become the mainstream product for liquid packaging. It can hold Class II and Class III dangerous goods. The maximum liquid density for Class II dangerous goods is 1.5g/cm3, and the liquid density for Class III dangerous goods is 1.8g/cm3. It can be directly loaded and unloaded by forklift, and can be stored in pallets. The bottom is equipped with a drain valve, the liquid drain is convenient, rapid, thorough, safe, easy to clean, and can be used for multiple turnovers, which is conducive to environmental protection.

Juncon Intelligent Equipment Co., Ltd. has been committed to making blow molding machines better, making blow molding machines more intelligent, more energy-saving, and more environmentally friendly. Actively respond to China's "carbon neutrality" environmental protection goal, reduce customer costs and create more value for customers.

September 12, 2022

July 25, 2022

please leave your message

Leave A Reply

Your email address will not be published. Required fiels are marked