Kayaks and fishing boat blow molding machines are popular products in recent years. They are tools for water recreation and water rescue as well as water rescue facilities. Because of the frequent floods in summer in our country, boats have also become a life-saving tool. Compared with rotomolding boats, blow molding boats have more durable materials and light weight, and the production efficiency of blow molding machines is fast, and energy saving and environmental protection.

Weight:Customized

Warranty:1 Year

MOQ:1 Set

Service:Installation & Training

Application:kayak, 1000L-2500L

Delivery Time:120 days

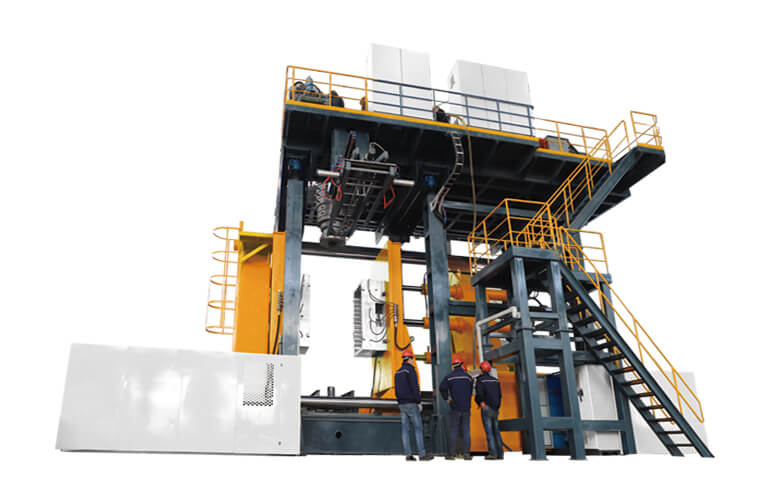

1.Parameters of JK-2500L Kayak Blow Molding Machine:

| Model | JK-2500L-1 | JK-2500L-2 |

| 2500L Kayak Blow Molding Machine | One Layer |

Two Layers |

| Max Product Size | 12*7*8.2m | 12*7*8.2m |

| Machine Dimension | 45ton | 50ton |

| Totle Power | 300kw | 330kw |

| Average Power Consumption | 150kw | 160kw |

| Accumulator Die Head | ||

| Accumulator capacity | 70L 50kg | 70L 50kg |

| Heating Load | 65kw | 75kw |

| Extrusion System | ||

| Screw Diameter | 150mm | 120/120mm |

| LD Ratio |

32:1 | 30:1 |

| Extruder Motor Power | 200kw | 132kw/132kw |

| Heating Power | 30kw | 60kw |

| Heating Power | 350kg/h | 400kg/h |

| Mold Clamping Unit | ||

| Clamping Platen Size | 1600*3000*100mm(customized) | 1600*3000*100mm(customized) |

| Max Mold Size | 1400*3100mm | 1400*3100mm |

| Clamping Force | 2200kn | 2200kn |

| Hydaulic System | ||

| Main Oil Pump Power | 40kw | 40kw |

| Small Oil Pump Power | 7.5kw | 7.5kw |

| Oil Tank Capacity | 1600L | 1600L |

2.Parameters of JK-2500L Kayak Blow Molding Machine:

1. The wall thickness control system from American MOOG is adopted to ensure the thickness of tank is more uniform and accurate.

2. The whole system adopts servo motor driver,compared with the traditional hydraulic system, the servo hydraulic system is safe and efficient, energy saving is more than 40%, and the noise is low.

3. The die head design as the product,and have the patent.New head design,uniform wall thickness control.

4. The full set of original SEIMENS control system ensures high quality, safe and stable operation, and has international after-sales service.

5. Adopt the boost cylinder, ensure large clamping force.

6. High production efficiency,Less scraps.

7. Convenient operation and stable equipment.

8. Low energy consumption, using advanced nm heating system and induction heater.

9. The unique hydraulic design avoids the complexity of the hydraulic system. The entire system adopts pressurized oil cylinders, which optimizes the hydraulic structure of the machine while providing a stronger clamping force.

10. Adopt the advance hydraulic valve from Japan.make sure the hydraulic system is more stable and reliable.

3.Applications of JK-2500L Kayak Blow Molding Machine:

JK-2500L blow molding machine can be used to prodcue kayaks, fishing boat and 1000L-2500L plastic products.

If you have any requirements about the blow molding machine, please contact me.

Jiaozhou, Qingdao, China

wendy@yancon.com

+86 18669866209