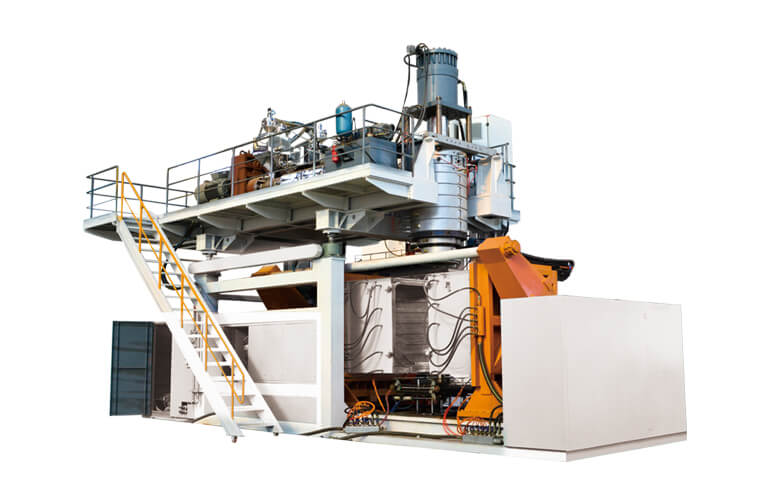

The JK-50L blow molding machine can achieve a maximum product volume of 50L, which is widely used in the production of 20L-50L oil tanks. The machine adopts storage die design. The maximum weight of the product that can be produced is 3.0kg. The machine adopts the third-generation MOOG wall thickness control system, which is accurate and stable.

Weight:Customized

Warranty:1 Year

MOQ:1 Set

Service:Installation & Training

Application:oil tank, stacking barrel

Delivery Time:100 days

1.Parameters of JK-50L Oil Tank Blow Molding Machine:

| Model | JK-50L |

| Specification | |

| Station | 1 |

| Dry cycle | 400PC/H |

| Output of HDPE | 130/160 KG/H |

| Weight | 14000KG |

| Size of Machine(L*W*H) | 5*2.4*3.8m |

| Die Head | |

| Max Die Diameter | 350mm |

| Die Head Heating Zone | 6 |

| Capacity of Accumulator Head | 6.6L |

| Die Head Heating Power | 21kw |

| Extrusion System | |

| Screw Diameter | 90mm |

| Screw Length/ Diameter Ratio | 25(28) L/D |

| Screw Heating Power | 17.4(20.5)kw |

| No.of Screw Heating Zone | 4(5) |

| Clamping Unit | |

| Platen Distance | 450-1000mm |

| Clamping Platen Size | 800*1000mm |

| Clamping Force | 300KN |

| Power Unit | |

| Hydraulic Pump Driving Power | 21kw+4 |

| Screw Motor Power | 37(45)kw |

| Total power | 100(111.5)kw |

| Average Power | 50(55)kw |

2.Advantages of JK-50L Oil Tank Blow Molding Machine:

1. Adopt the SEIMENS plc control system,all functions such as process setting, change, retrieval, monitoring, fault diagnosis are realized on the touch screen, the working principle of no-point contact, and the components are durable

2. Adopt the new design of the screw,make sure the high plasticizing.

3. Use HMWHDPE to ensure that the productions are stronger and longer life.

4. Adopt the Aluminum mold ,cooling faster ,the productivity is higher.

5. The customer can choose the automatic cutting machine for saving the labour.

6. The wall thickness control system from American MOOG is adopted to ensure the thickness of tank is more uniform and accurate.

7. The whole system adopts servo motor driver,compared with the traditional hydraulic system, the servo hydraulic system is safe and efficient, energy saving is more than 40%, and the noise is low.

8. The die head design as the product,and have the patent.New head design,uniform wall thickness control.

9. The full set of original SEIMENS control system ensures high quality, safe and stable operation, and has international after-sales service.

10. Adopt the boost cylinder, ensure large clamping force.

11. High production efficiency,Less scraps.

12. Convenient operation and stable equipment.

13. Low energy consumption, using advanced nm heating system and induction heater.

14. The unique hydraulic design avoids the complexity of the hydraulic system. The entire system adopts pressurized oil cylinders, which optimizes the hydraulic structure of the machine while providing a stronger clamping force.

15. Adopt the advance hydraulic valve from Japan.make sure the hydraulic system is more stable and reliable.

3.Applications of JK-50L Oil Tank Blow Molding Machine:

The JK-50L blow molding machine can achieve a maximum product volume of 50L, which is widely used in the production of 20L-50L oil tanks.

If you have any requirements about the blow molding machine, please contact me.

Jiaozhou, Qingdao, China

wendy@yancon.com

+86 18669866209