At first, when I received the customer's inquiry, I thought that this order requirement would not be difficult for our company, because we have made many double-ring barrel blow molding machine, single-layer machine , double-layer machine, and the technology is very mature. Everything seems to be flowing-quote, negotiate, agree on details, invite factory inspection and place an order. However, the requirements of customers have changed with the change of the market. Customers put forward their own opinions: there are too many single-layer and double-layer double-ring barrels on the market, and the competition is fierce. If customers want to occupy the market, they must come up with better products, so require three-layer double-ring barrel blow molding machine, and must meet the EU's CE certification requirements. Under the epidemic situation, the entire project fell into a difficult and long time negotiation stage.

So why do customers choose Juncon blow molding machine from so many suppliers?

The client initially visited several companies at the same time and negotiated with several suppliers. We have been communicating by e-mail, and there is no substantial effect, and customers have always objected to our strength. Our company made a decision quickly . Although the customer cannot come to China to inspect the factory in person, we can conduct the factory inspection through a video call. We invite customers to visit our factory through video calls, from the processing workshop, to the assembly workshop, to the test machine. Every step is shown to customers without reservation. At the same time, we have also passed several Google meetings and worked with our technical team to help customers solve problems and dispel their doubts. In the process of communication, it can be seen that customers are still very satisfied with our service and the company's technical strength and processing capabilities. Customers can finally choose us, and it is also determined by comparison and certification research. So what's concern do customer care about? how do we solve customers' concerns one by one?

1. There are few three-layers double-ring barrel blow molding machine in the market. Why do customer believe that we can do it?

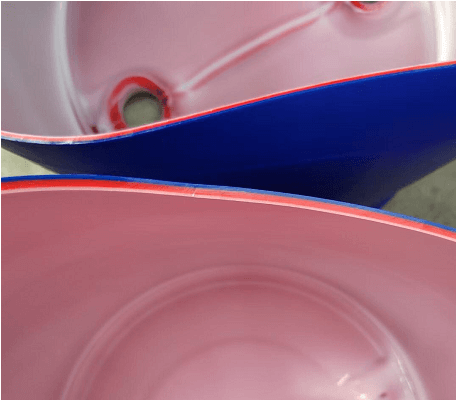

There is little market demand for the three-layers double-ring barrel blow molding machine. We have never done it, but we have already made 3-layers civilian water tank blow molding machines before, even 4 layers, 5 layers, 6 layers, and 7 layers , 8-layers blow molding machines, and they are very mature and have long been unique in the market. Although the double-ring barrel is in the field of chemical barrels, the core of the blow molding machine is the die head, and our multi-layers die head design is leading, we have rich experience, we can completely transplant the technology to the double-ring barrel die head, and Innovative, optimized design on this basis . Customers were shocked when they saw our 6-layers and 7-layer blow molding machine, so they were not worried about our three-layers double-ring barrel blow molding machine.

2. Whether the output of the double L-ring blow molding machine can meet the customer's requirements

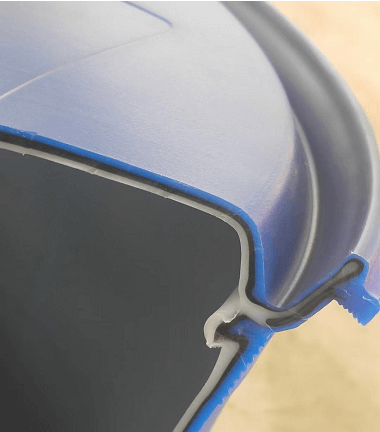

Customer have high requirements for the double ring drum blow molding machine, not only for the number of layers of machine, but also for the output of the drum blow molding machine. This requires our machine to have higher plasticizing capacity and better mold cooling efficiency. Then for the machine, we need to optimize the extruder screw design to ensure a higher plasticizing rate. For the mold, we use an aluminum mold and optimize the cooling water channel design. Improve cooling efficiency. At the same time, in order not to affect the drum quality, we also developed a secondary cooling and setting device. Improve production efficiency while ensuring product quality. It can produce 25~30 pieces per hour to meet customer requirements.

3. Whether the energy consumption of the blow molding machine can meet the customer's standard

The high efficiency of blow molding machine often brings high energy consumption. But customers often want to reduce the production costs. In response to customer requirements, we have made significant improvements to the two parts of the machine that consume more power, changing the main oil pump to servo control and replacing the screw heater to an infrared nami heater, which greatly reduces energy loss. After testing, compared with the traditional blow molding machine, the power consumption has been reduced by 40%-50%. Although the price of the machine has gone up, the customer is still very satisfied. Because customers focus on longer-term economic benefits.

4. Whether Juncon blow molding machine can be exported to Europe and the United States, and whether it can meet the CE standard

Our group company's machine has been exported to the United States before, and our machine is also CE certified by SGS. Therefore, the equipment should fully meet the requirements of CE certification. In order to dispel customers' concerns, we promise that customers can send a third-party testing agency to inspect the machine after the production of the machine is completed .Ensure all parts meet the CE standards. This is our confidence in our own machine and our responsibility to our customers.

5. Whether the processing capacity of the equipment is sufficient and can be delivered on time, especially under the epidemic situation

Video calling visit of the factory is to break the doubts of customers. We have a workshop of more than 50,000 square meters and a processing workshop of 10,000 square meters, which can process and produce more than 100 various type machines every year. Although under the background of the epidemic, our government and factories have taken active anti-epidemic measures. Since the epidemic, the factory has not delayed any production progress. Make sure every customer can deliver on time.

6. After-sales service, how to solve after-sales problems

We have an after-sales service team of more than 20 people, and we promise that we can send our engineers to customer factories to provide services without severe epidemics and government control. And our after-sales service is free of charge. At the same time, our after-sales team is responsible for every machine from our factory. With 24-hour online service, ensure customers can find us.

7. how to inspection of machine

In response to this solution, it is also a concern of many customers in the context of the epidemic. Our current solution is to test the machine through video. We communicate with customers through live stream and test the machine according to customer requirements. Allow customers to see every part of their blow molding machine and check every function of the machine. At the same time, we also support third-party inspection, customers can find third-party agencies to inspect their own machines. We promise that all the indicators can meet the customer's requirements before delivery. And our client chose the second way.

Negotiations are long, and trust comes from mutual communication and understanding. Juncon Intelligent Equipment Co., Ltd. solves blow molding machine problems for our customers in the spirit of ingenuity. At the same time, we also welcome new and old customers to give us more opportunities and more challenges. I believe that our team will study carefully and solve every problem and concern of customers one by one.

please leave your message

Leave A Reply

Your email address will not be published. Required fiels are marked