With the development of modern industry, more and more plastic production enterprises have higher and higher requirements for blow molding machine . Customers' higher and higher requirements for blow molding machine energy consumption, labor, noise, environment, safety, etc., promote the development of blow molding machine technology in the direction of energy saving, environmental protection and low carbon. Customers require blow molding machines to be more and more automated, safer and more energy-efficient, which reduces production costs and protects the environment.

Compared with traditional rotomolding machines, blow molding machines are already very energy-saving and environmentally friendly. However, with the global emphasis on environmental governance, JUNCON blow molding machines have been innovating and constantly adopting new technologies. So let's compare the advantages of the new servo system compared to the traditional technology. We focus on eight aspects for comparison.

Advantage Comparison | ||||

|

Servo Control Hydraulic System |

Inverter Control Hydraulic System |

Star -Triangle Control Hydraulic System |

||

1 |

Control Unit |

The Servo inverter |

The Siemens Inverter |

The Contactor |

|

2 |

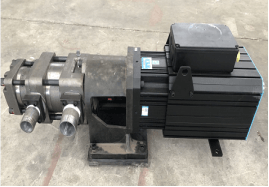

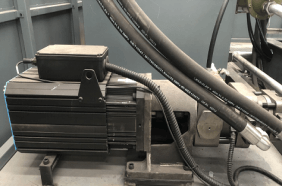

Motor and Pump |

Synchronous motor |

Traditional Siemens motor |

Traditional Siemens motor |

|

3 |

Stability |

Position,low speed and high speed is stable |

General stability |

Not stable |

4 |

Control Precision |

High precision |

General precision |

Low precision |

5 |

Adaptability |

Strong anti-overload Ability and withstand Three times rated Torque load |

Withstand small overload And torque load,but it is difficult to control |

Can not withstand the overload And torque load |

6 |

Energy Saving |

Save 30%-50% Power consumption |

Save 10%-20% Power consumption |

No saving |

7 |

Temperature and Noise |

Small noise and low Temperature when Machine product |

High temperature |

Big noise and high temperature After running longtime |

8 |

Carbon Emission |

Meet the criterion Consumption lowest |

Consumption Normal |

Consumption high |

Why servo system is energy saving?

Servo motor is also called executive motor. In the automatic control system, it is used as an executive component to convert the received electrical signals into the angular displacement or angular velocity output of the motor shaft. Its main characteristics are that there is no rotation when the signal voltage is zero, and the speed decreases uniformly with the increase of the torque.Servo motor can control speed and position accurately.

It means the servo system can adjust the working power according to the work needs.Unlike the ordinary control methods is always running by same speed when product.so can saving power and energy to make sure the blow molding machine running stable.

September 12, 2022

July 25, 2022

please leave your message

Leave A Reply

Your email address will not be published. Required fiels are marked