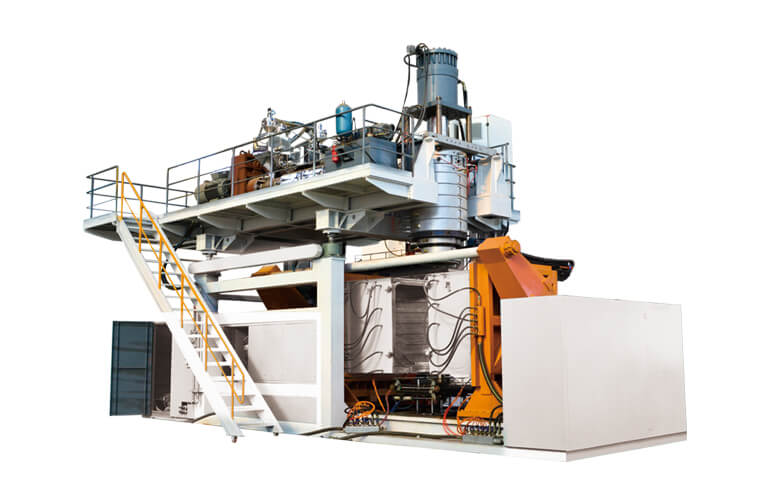

For septic tank manufacturers, septic tank blow molding machines, as fixed equipment, account for a large share of septic tank production costs. Therefore, doing a good job in the maintenance of the septic tank blow molding machine and extending the service life of the septic tank blow molding machine is an important part of the production that septic tank manufacturers must have.

In the process of septic tank production, many small manufacturers do not have a complete set of production operation specifications and plans for septic tank blow molding machines. Therefore, various failures often occur, and the service life is greatly reduced.

In fact, not only septic tank blow molding machines, but other plastic product manufacturers are applicable to these maintenance methods.

The following will give you a detailed summary of the maintenance method of the plastic septic tank blow molding machine.

For plastic septic tank manufacturers, it is necessary to establish a complete blow molding machine operation process and maintenance rules. Therefore, the operation of the blow molding machine is generally from three aspects: before, during and after startup. To formulate a reasonable operation process.

1. Maintenance plan for septic tank blow molding machine before starting

Before starting the machine, do a good job of lubricating all parts. Check whether the screws of each part are firm and whether the screws are loose. Also check switches, pneumatic components, etc. Try to avoid emergency stop, frequent switching, etc.

2. Maintenance process during startup of septic tank blow molding machine

The septic tank blow molding machine usually uses some plastic raw materials such as polyethylene and polypropylene. By melting the raw materials to form a parison, then blowing and maintaining the pressure, the molten plastic is solidified and formed in the mold. In the process of starting the plastic septic tank blow molding machine, if there is any problem, it should be stopped in time.

3. Maintenance plan after the septic tank blow molding machine is produced

After the production is completed, the cleaning work must be done well. Clean the machine head and mold cavity, and clean up the residual raw materials in time. After cleaning the inner and outer walls of the pipeline in time, stop the machine. Try to avoid the emergency stop, emergency opening and frequent switching of the blow molding machine, and do a good job of cleaning after use.

The maintenance of plastic septic tank blow molding machine is a more important step in the production of our plastic blow molding machine. If you have any demand for septic tank blow molding machine, please contact Juncon.

September 12, 2022

July 25, 2022

please leave your message

Leave A Reply

Your email address will not be published. Required fiels are marked