Blow-molded plastic pallets can be mainly divided into Double-sided Pallet, Double-sided Pallet and so on. Juncon will introduce the classification and parameters of blow-molded plastic pallets in detail.

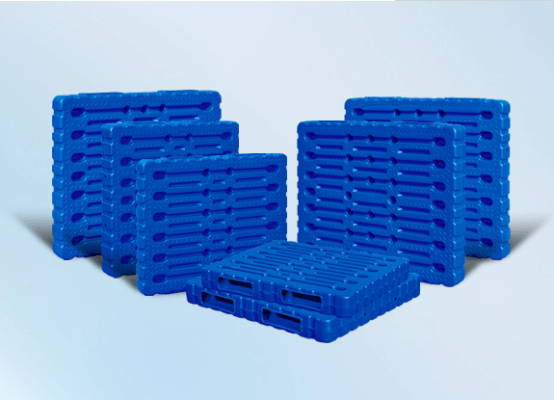

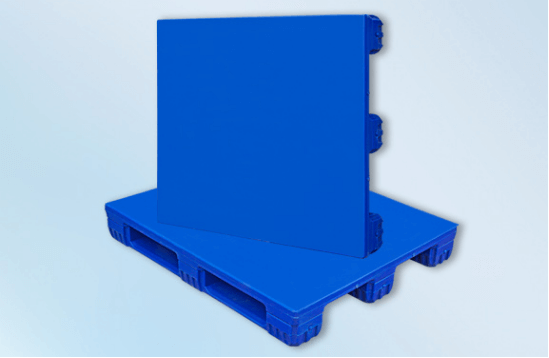

1. Double-sided Pallet:

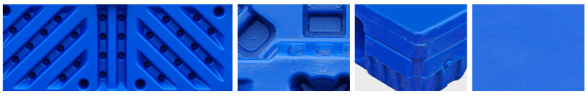

1) The shape is novel and unique, the structure design is reasonable, the surface is grooved, and there are anti-slip patterns, so the items are not easy to slip off.

It is suitable for use with mechanical forklifts, manual hydraulic handling forklifts and automatic palletizers to complete the handling, turnover and stacking of goods.

2) The product has excellent impact resistance, good wear resistance and weather resistance, and can be used in the environment of -40℃-60℃, especially suitable for use in cold areas and refrigerated warehouses.

Meet the requirements of sanitary inspection, with excellent chemical resistance, moisture resistance, no rust, easy to wash, no mildew.

| Type | Size(mm) | Weight(Kg) | Dynamic Load(T) | Static Load(T) | Fork Size(mm) | Center Distance of Fork(mm) |

| P1210 | 1200*1000*150 | 18 | 2 | 6 | 295*85 | 235 |

| P1212 | 1200*1200*150 | 22 | 2 | 6 | 295*85 | 235 |

| P1311 | 1300*1100*150 | 23 | 2 | 6 | 295*85 | 335 |

| P1412 | 1400*1200*150 | 25 | 2 | 6 | 300*90 | 440 |

| P1414 | 1400*1400*150 | 27 | 2 | 6 | 300*90 | 540 |

| P1513 | 1500*1300*150 | 35 | 2 | 6 | 300*90 | 535 |

| P1614 | 1600*1400*150 | 40 | 2 | 6 | 300*90 | 740 |

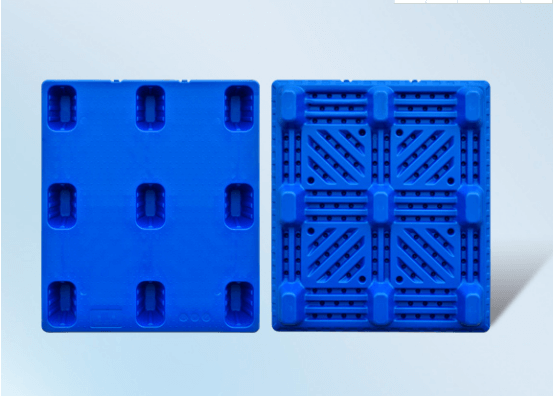

2.Plastic Pallet Nine Foot Pallet

1) The nine corner design is convenient for stacking and stacking and saves space.

2) The self weight is 8.5Kg, which can be adjusted according to the needs of customers, with ultra-high cost performance.

3) Both manual forklift and mechanical forklift can be used for convenient transportation, which greatly facilitates the handling, turnover, stacking and storage of goods.

4) The products are widely used in petrochemical, bio-medicine, food and so on.

| Type | Size(mm) |

Weight (Kg) |

Dynamic Load (T) |

Static Load (T) |

Fork Size (mm) |

Center Distance of Fork (mm) |

| P1210 | 1200*1000*145 | 8.5 | 1 | 3 | 267*97/288*97 | 465/405 |

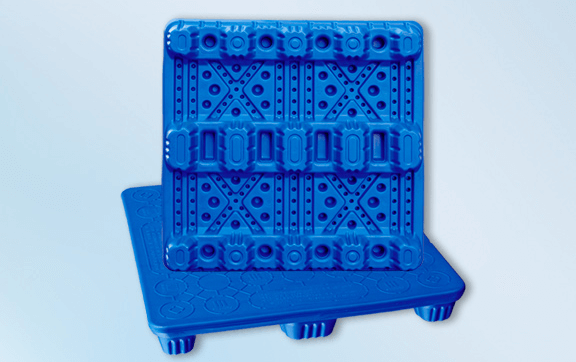

3.Two-way Fork Pallet

High strength and low temperature resistance Three-layer co-extrusion blow molding at one time. The main console of the centralized feeding system strictly adjusts the flow rate and proportion of the raw materials in the inner and outer layers according to the set parameters. Full digital control, higher efficiency and better quality. Adopt multi-layer co-extrusion experience with forced feeding trough and multiple safety pressure protection devices for more than 50 years.

Independent research and development, private customized services at home. It is specially tailored for pharmaceutical and food workshops to meet the high cleanliness requirements of customers. The upper plane is a flat design with anti-skid and diversion measures, which is convenient for cleaning, stacking and transportation.

The overall outer surface is completely closed, with a high degree of cleanliness, and will not provide a breeding ground for microorganisms and other pests.

It is light and can be used by forklifts and carts. It has a strong carrying capacity and is not easy to damage at low temperatures. It can reduce logistics costs for you by extending the service life of products. Widely used in petrochemical, bio-medicine, food and aquatic products, fruits and vegetables, mechanical hardware, electronic appliances and other industries.

| Type | Size(mm) | Weight(Kg) | Dynamic Load(T) | Static Load(T) | Position | Fork Size(mm) | Center Distance of Fork(mm) |

| P1111 | 1100*1100*145 | 14 | 1.5 | 3 | Two Way Fork | 215*90 | 484 |

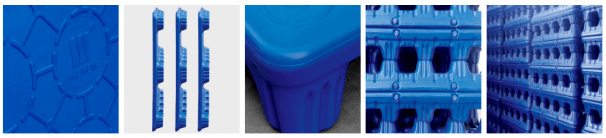

4. Flat chuanzi (built-in steel pipe) Blow Molding Tray

High strength, low temperature resistance, three-layer co-extrusion, one-time blow molding. The central control console of the centralized feeding system adjusts the flow rate and proportion of raw materials in the inner and outer layers in strict accordance with the set parameters. All digital control, higher efficiency and better quality. The blow molding machine with forced feed chute and multiple safety pressure protection devices and more than 50 years of multi-layer co-extrusion experience is adopted.

Independent research and development, private customized service home. The built-in steel pipe breaks the only disadvantage that the blow molding tray can not be put on the shelf. The upper plane is of flat design, which is convenient for cleaning, stacking and transportation. Four way forklift, manual forklift and mechanical forklift can be used for convenient transportation, which greatly facilitates the handling, turnover, stacking and storage of goods.

Widely used in petrochemical, biomedicine, food and aquatic products, fruits and vegetables, machinery and hardware, electronic and electrical appliances and other industries.

| Type | Size(mm) | Weight(Kg) | Dynamic Load(T) | Static Load(T) | Position | Fork Size(mm) | Center Distance of Fork(mm) |

| Two-way 1210 | 1200*1000*165 | 23 | 1.5 | 5 | Four Way Fork |

350*95 250*120 |

515 420 |

September 12, 2022

July 25, 2022

please leave your message

Leave A Reply

Your email address will not be published. Required fiels are marked